Concrete Surface Finishing | How to Finish Concrete Surface

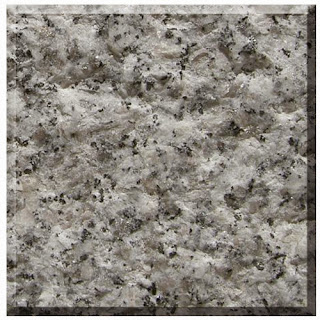

Concrete is essentially an artificial stone. It is subjected to weathering agents like natural stone. Therefore, the concrete surface should be given some finishing. The concrete surface finishing is of various types such as plastered finishing, shuttering finishing, dressed finishing and granolithic finishing.

Plastered Finishing:

This is a very common type of concrete surface finishing. There are different types of plaster in use. Sometimes, the plastered surfaces are sand rubbed.

Shuttering Finishing:

If the shuttering is very correctly made and the placing and compacting are done properly, the surface gives a good appearance when the shuttering is removed. Pre-cast concrete sections may simply be jointed at their side, with their surface left in the same conditions as when cast. Sometimes, shuttering finishing desired for important type of constructions, such as overhead R.C.C. etc.

Dressed Finishing:

In this type of finishing, the surface is given some of ornamental touch with the help of dressing.

Granolithic Finishing:

In this type of finishing, the concrete surface is finished when green. Common types of finishing are: (1) trowel finish with neat cement and (2) slightly rough finish with a wooden float. These finishings are generally used in dwelling houses and factory and industrial buildings, ware houses, roads, institutions, etc. To increase the resistance of wear and rear, small quantities of silicate compounds of sodium and magnesium are used. Sometimes cement during the setting action, combines with the solution and forms calcium silicate which forms a hard and wear and tear resisting surface.

Plastered Finishing:

This is a very common type of concrete surface finishing. There are different types of plaster in use. Sometimes, the plastered surfaces are sand rubbed.

Shuttering Finishing:

If the shuttering is very correctly made and the placing and compacting are done properly, the surface gives a good appearance when the shuttering is removed. Pre-cast concrete sections may simply be jointed at their side, with their surface left in the same conditions as when cast. Sometimes, shuttering finishing desired for important type of constructions, such as overhead R.C.C. etc.

Dressed Finishing:

In this type of finishing, the surface is given some of ornamental touch with the help of dressing.

Granolithic Finishing:

In this type of finishing, the concrete surface is finished when green. Common types of finishing are: (1) trowel finish with neat cement and (2) slightly rough finish with a wooden float. These finishings are generally used in dwelling houses and factory and industrial buildings, ware houses, roads, institutions, etc. To increase the resistance of wear and rear, small quantities of silicate compounds of sodium and magnesium are used. Sometimes cement during the setting action, combines with the solution and forms calcium silicate which forms a hard and wear and tear resisting surface.

Comments

Post a Comment